Built to Solve Real Manufacturing Challenges

Complex Processes

Coordinate multi-step, high-variation workflows with streamlined, lean-aligned execution.

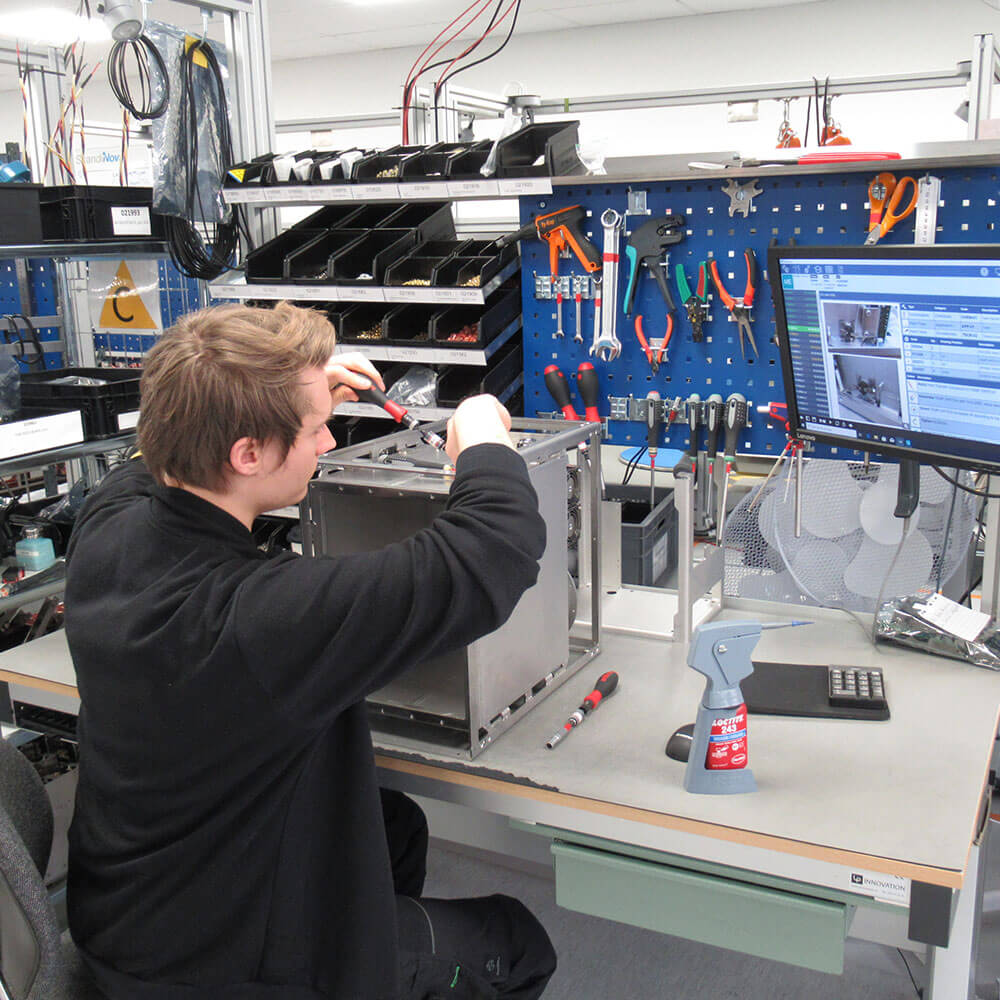

Paperless Systems

Eliminate paper instructions with digital work instructions and intelligent version control.

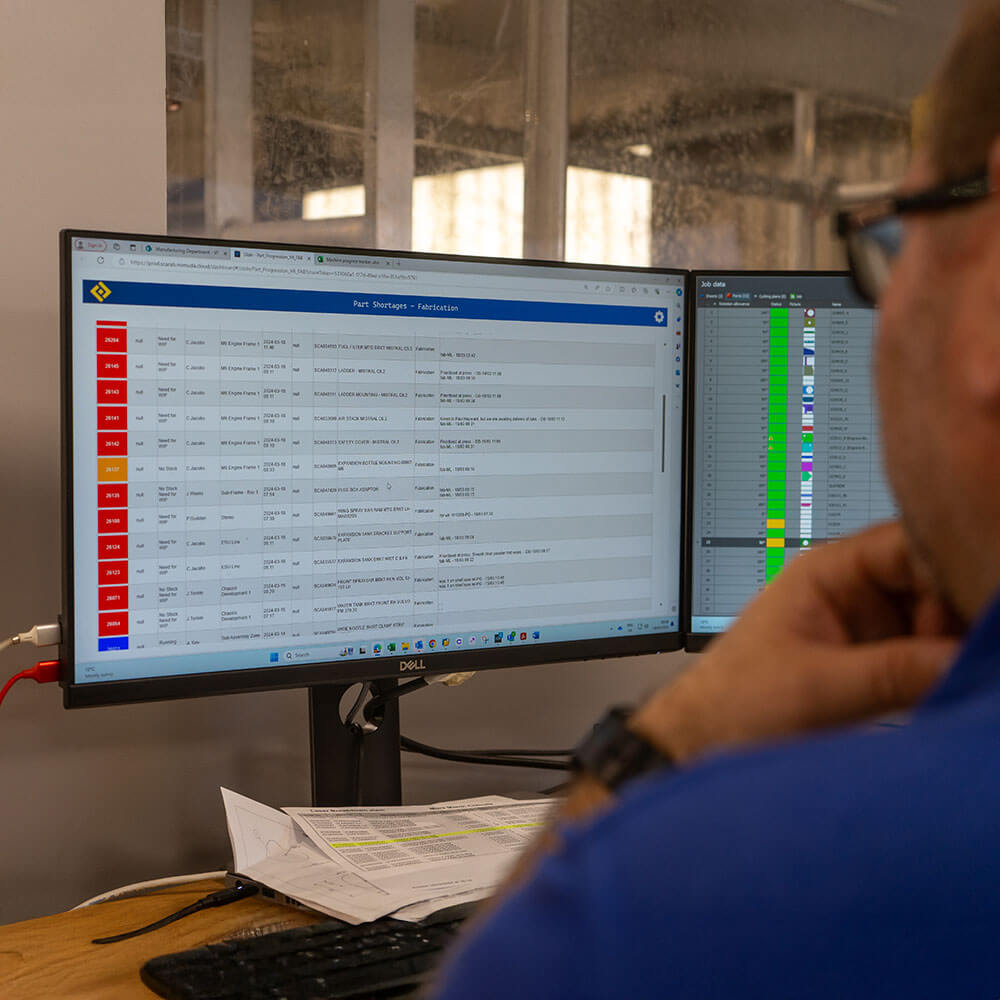

Real Time Data & Visibility

Track operations and performance live to support continuous improvement and rapid decision-making.

Quality and Governance

Ensure compliance with industry standards through traceable, audit-ready processes.

A Smart MES for Smarter Operations

Standardize Complex Workflows

Enforce digital work instructions across multiple product lines and facilities. VisualFactory reduces variation by ensuring that every operator follows the same validated process, with automated version control and embedded approvals for change management.

Real-Time Operational Visibility

Access dashboards and live production data for full visibility into WIP, cycle times, and OEE metrics. VisualFactory empowers frontline and leadership teams to identify bottlenecks, respond faster, and drive continuous improvement through real-time insights.

Tailored for Lean and High-Mix Manufacturing

Built for flexibility, VisualFactory excels in environments with high product variety, small batch sizes, or complex assembly steps. It supports lean principles such as takt time, standard work, and error-proofing at scale.

Streamline Quality and Compliance

Maintain compliance with industry and regulatory standards like ISO, FDA, and ITAR. VisualFactory automates data capture, traceability, and audit trails eliminating manual checks and enabling first-time-right manufacturing.

A Solution Designed to Perform Across Industries

Aerospace & Defence

Support ITAR compliance and build traceable, quality-assured assemblies.

Automotive & Transport

Enable lean lines and real-time performance tracking across production cells.

Consumer Products

Standardize processes and reduce rework in fast-paced environments.

Discrete Manufacturing

Enhance flexibility with digitally controlled, variant-rich workflows.

High Tech & Electronics

Ensure right-first-time builds and full component traceability.

Industrial Products

Optimize shop floor control in low-volume, high-complexity operations.

Medical Device

Maintain FDA and ISO compliance with validated process control.

Pharmaceutical

Achieve GMP and batch-level traceability from materials to finished goods.

Seamless Integration with IoT & ERP

Connect VisualFactory with your ERP to automate BOMs, work orders, and part usage tracking. Integration with MQTT-based IoT systems ensures real-time operational data flow and visibility.

Cloud or On-Premise MES

Choose managed cloud (ISO27001 certified) for hassle-free deployment, or opt for on-premise for full control and ITAR compliance.

What Clients Say About VisualFactory

Case Studies

Frencken

Frencken Mechatronics’ production team needed an MES that was going to provide them with full traceability to ensure that their medical products satisfy FDA guidelines.

Read more

Volvo

“The possibilities are endless with the constant development of new modules – it is truly a one stop shop for all of your lean manufacturing needs.” – Manufacturing Engineer Garry Moore.

Read more

Saab Seaeye

VisualFactory has reduced Saab Seaeye’s rework costs by more than a quarter of a million dollars by helping them to achieve right-first-time quality.

Read more