Build with Confidence, Deliver with Precision

In regulated and high stakes manufacturing environments, quality isn’t optional. NoMuda’s VisualFactory helps manufacturers embed quality control at the heart of their production systems, by combining live operator guidance, real time error prevention, and full process traceability into one MES software. Whether you’re building aircraft components, robotics, or medical devices, VisualFactory ensures your teams follow the correct process, use the right materials, and log critical data, all without disrupting workflows and takt time.

Resolve Key Manufacturing QMS Challenges

Limited Traceability

Automatically log every action, input, and result during production, enabling full digital audit trails for compliance, recalls, and customer assurance.

Inconsistent Process Execution

Ensure every product is built the same way, every time. VisualFactory enforces standardized processes and validates every critical step.

Fragmented Data Collection

Ditch fragmented checklists and paper logs. Capture quality and compliance data directly at the workstation in real time.

Defects and Rework

Reduce unintentional quality defects and rework by guiding operators through validated processes that prevent errors before they happen.

Designed for Quality Focused Production Environments

Live Process Validation

Operators receive step by step instructions backed by in process checks. From torque values to material scans, every detail is verified right where the work happens.

Intuitive Non Conformance Detection

NoMuda’s quality management system alerts operators to missing, incorrect, or skipped steps, keeping quality on track and a weight off their shoulders.

Paperless Compliance

Capture quality, inspection, and traceability data as part of the workflow. No manual transcription, no paperwork errors – just seamless digital compliance.

Documented Adherence to Optimal Processes

Go beyond ‘best effort’ and evidence to auditors that every operator has followed the approved and documented process across your production line.

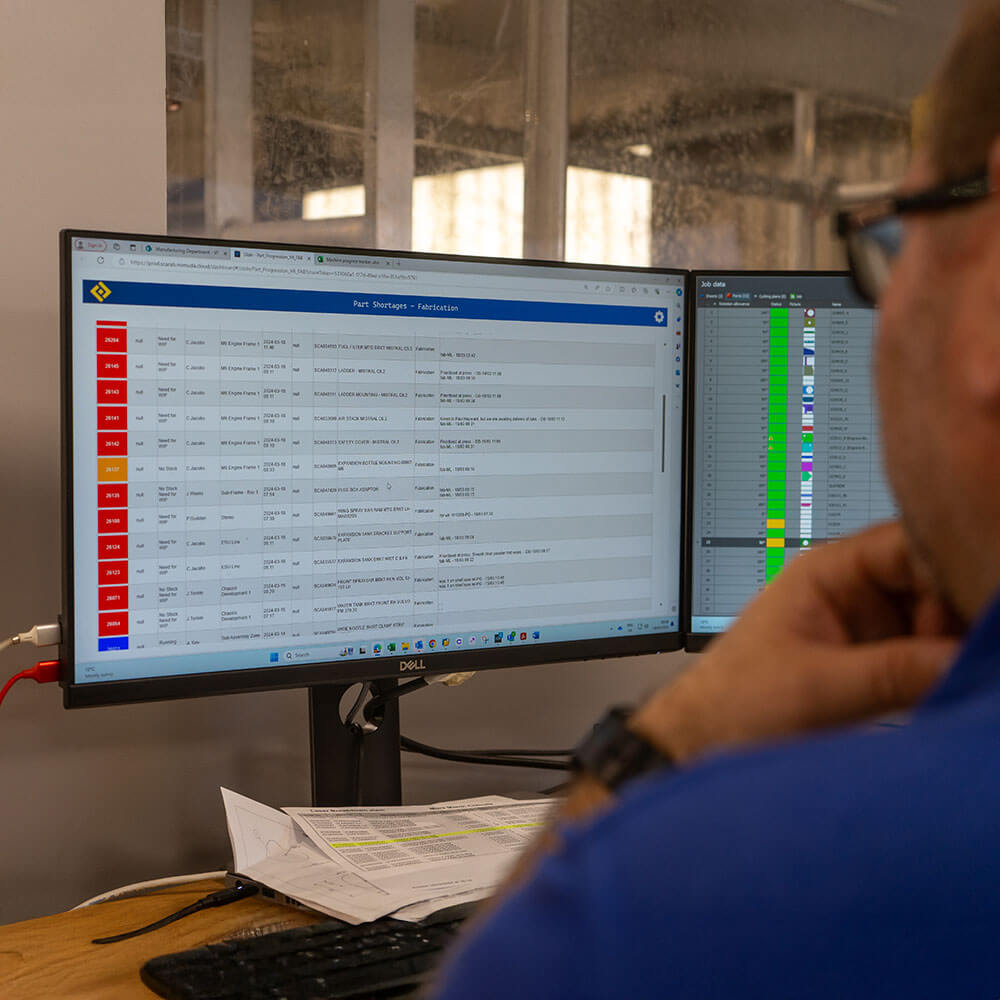

How MES Improves Quality Execution

Integrate with ERP and Quality Systems

Push work orders and quality checkpoints straight from planning tools into operator workflows.

Guide and Validate on the Line

Deliver tailored instructions and verifications to match each unique build, product variant, or customer requirement.

Capture Live QMS Data

Log inspections, serial numbers, material usage, and approvals at the source, in real time.

Trace, Report, and Improve

Generate compliance ready records and actionable reports that drive continuous improvement and quality reviews.

Real Business Impact from Smarter Quality Control

Reduce Defects and Escape Rates

Built in error prevention and validation means less rework, fewer recalls, and stronger customer trust.

Simplify Audits and Compliance

With full traceability baked in, audits are no longer a scramble. Data is accurate, digital, and always inspection ready.

Improve Right First Time Rates

Operators are guided to success from the start, with visual instructions, checks, and alerts that help them get it right the first time.

Empower Operators Without Slowing Them Down

An intuitive QMS software interface delivers guidance that enables confident execution without extra steps or confusion.

Standardize Quality Across Shifts and Sites

Remove unwanted variability from the equation. NoMuda’s VisualFactory ensures the same high standard is applied across all teams and facilities.

Support Lean, Scalable Quality Management

Add quality control without adding complexity. Through VisualFactory, you can action ongoing quality improvements and Kaizen as your operations grow.

Partnering with Leaders in

Aerospace & Defense

Ensure compliance with aerospace and defense requirements, like AS9100 and ITAR.

Aerospace & Defence

Automotive & Transport

Enhance automotive and transport delivery performance, with intuitive dashboards that effectively measure OEE.

Automotive & Transport

Consumer Products

Scale confidence and enhance product launches with paperless instructions and integrated quality checks.

Consumer Products

High Tech & Electronics

Improve compliance, scale precision and agility and maintain end‑to‑end traceability for high tech electronics.

High Tech & Electronics

Industrial Products

Transform industrial production with a solution designed for complexity, performance and real time visibility.

Industrial Products

Medical Device Manufacturing

Build safe and compliant products that meet FDA and ISO requirements, with skill validations and audit trails.

Medical Device Manufacturing

Pharmaceutical Manufacturing

Digitize pharmaceutical batch production with a program that supports compliance on the floor.

Pharmaceutical Manufacturing

What Clients Say About VisualFactory

Case Studies

Parker Meggitt

As a world-leader in innovative technologies, products and services for the Aerospace, Defence and Energy Markets, product traceability is key for Meggitt.

Read more

Racal Acoustics

Racal Acoustics have replaced over 13000 pages of documentation in the manufacturing process with the implementation of VisualFactory’s digital work instructions.

Read more

ScandiNova

ScandiNova is a leading provider of solid-state pulsed power solutions. The deployment of VisualFactory has streamlined processes and reduced training times for new operators.

Read more