Built-In Traceability with Compliance

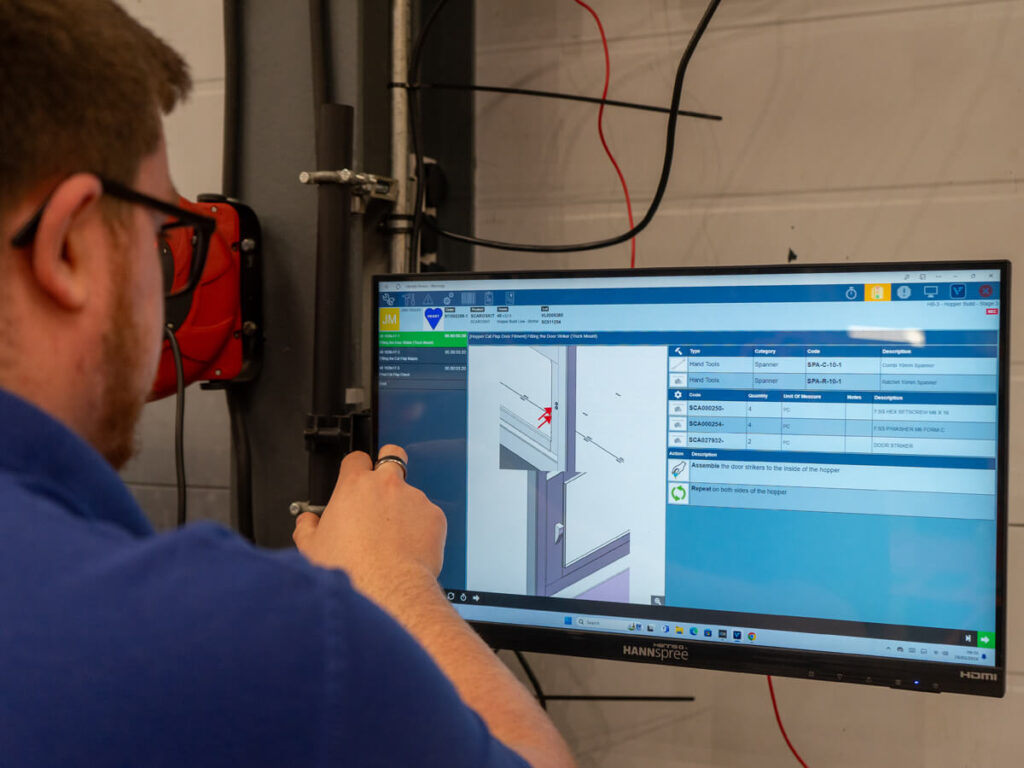

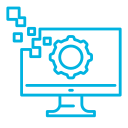

NoMuda’s VisualFactory MES system captures exactly who performed a task, when, and with what materials, as well as measuring specific details like serial numbers. From supply chain inputs to operator checks, VisualFactory provides full compliance by increasing traceability throughout the entire workflow. VisualFactory has been designed for regulated, high-mix, high-stakes environments, enabling businesses to boost their digitization and efficiency.

Challenges That Traceability and Compliance fixes

Unreliable Records

Reduce paper trails and gaps with digital traceability built into every workflow.

Audit Stress

Always be prepared for audits and evaluations with real-time compliance records.

Recall Risks

Gain the ability to quickly trace errors with complete data trails, from supplier to shipment.

Manual Part Verification

Use barcode scanning and built-in rules to digitally confirm the correct parts and tools.

Smarter Traceability for Real-World Operations

Consistent, Automated Traceability

Benefit from a product traceability software that captures every step, decision, and material as it happens.

Continuous Compliance

Regardless of your sector, meet regulatory compliance with real-time digital documentation and process validation.

Live Part and Material Verification

Ensure every component is correct through automated checks on part numbers, suppliers, or configurations.

Fully Integrated With the Way You Work

Traceability software works alongside your teams, tools, and ERP from the start, without extra admin requirements.

How Traceability and Compliance Connect Your Operation

Receive Configured Work Order From ERP

Automatically integrate project management, risk management, and supply chain operations into your core business processes.

Confirm Inputs in Real Time

Continuously scan and verify components, lot numbers, and supplier data at all points in time.

Record Every Step and Signature

Track operator actions, approvals, tool settings, and inspections throughout project timelines.

Audit With Confidence

Streamline efficiencies by searching complete digital histories by part, batch, order, or operator.

Why Manufacturers Choose VisualFactory

Minimize Recall Impact

Identify root causes quickly with complete full product and supply chain traceability software.

Automatically Prove Compliance

Create digital audit trails when needed, from regulated checks to operator approvals.

Increase First-Time Accuracy

Prevent mistakes by implementing processes and verifying every input at the point of use.

Support Your Workforce

VisualFactory is built for real operators in real environments, making traceability easy to follow and adopt.

Trusted by Manufacturers Who Prioritize Quality

Aerospace & Defense

Ensure compliance with aerospace and defense requirements, like AS9100 and ITAR.

Aerospace & Defence

Automotive & Transport

Enhance automotive and transport delivery performance, with intuitive dashboards that effectively measure OEE.

Automotive & Transport

Consumer Products

Scale confidence and enhance product launches with paperless instructions and integrated quality checks.

Consumer Products

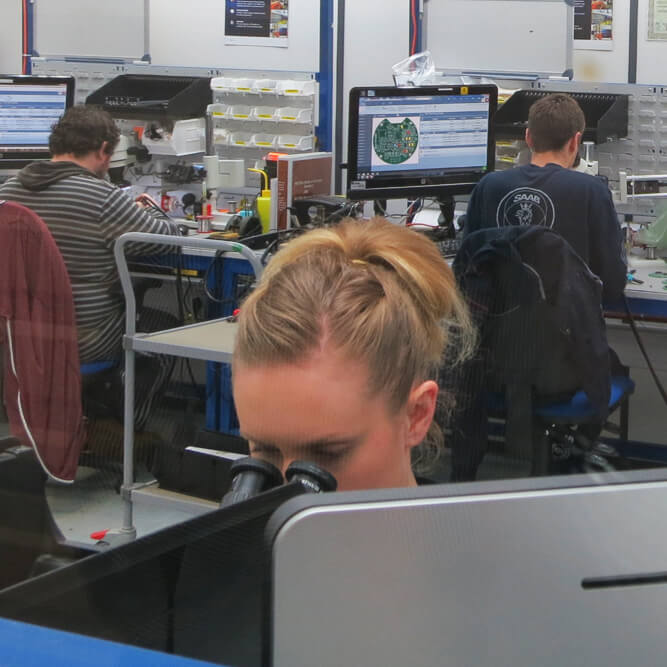

High Tech & Electronics

Improve compliance, scale precision and agility and maintain end‑to‑end traceability for high tech electronics.

High Tech & Electronics

Industrial Products

Transform industrial production with a solution designed for complexity, performance and real time visibility.

Industrial Products

Medical Device Manufacturing

Build safe and compliant products that meet FDA and ISO requirements, with skill validations and audit trails.

Medical Device Manufacturing

Pharmaceutical Manufacturing

Digitize pharmaceutical batch production with a program that supports compliance on the floor.

Pharmaceutical Manufacturing

What Our Customers Say

See Traceability in Action

Saab Seaeye

VisualFactory has reduced Saab Seaeye’s rework costs by more than a quarter of a million dollars by helping them to achieve right-first-time quality.

Read more

Thyssenkrupp

Thyssenkrupp’s implementation of NoMuda VisualFactory including digital work instructions, and the complimentary modules has resulted in improved production processes.

Read more

Hensoldt

HENSOLDT UK – a world leader in maritime navigation. VisualFactory has enabled greater control over their shop floor process, improving manufacturing efficiency.

Read more