MES for Process Manufacturing

Connecting planning systems with the shop floor, VisualFactory transforms work orders into real-time, executable instructions tailored to every build. NoMuda’s leading manufacturing execution system process flow software features a human-centric interface with live data capture, allowing manufacturers to gain end-to-end visibility, reduced errors, and a production line that runs with greater control, speed, and precision.

Solving Work Order Processing Software Challenges

Disconnected Production Data

Eliminate the need for manual handoffs by syncing ERP and the shop floor for accurate, real-time execution.

Manual Work Instructions

Remove printed paperwork with live, validated instructions unique to each configured product.

Complex Product Variants

Automatically modify work steps and tools to match each unique order and build variant.

High Operator Dependency

MES process flow solutions help to support teams with guided workflows, without the need for memorization or existing knowledge.

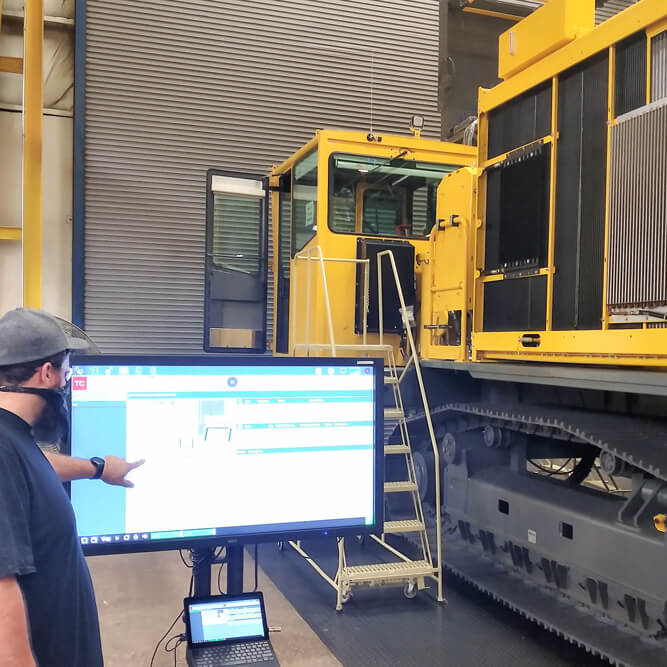

Purpose-Built for Real-World Manufacturing

Support High-Mix, Low-Volume Builds

VisualFactory adjusts in real-time to changing product specifications and configuration rules, minimizing delays and costly rework.

Created for Operators

Designed for ease of use, the software simplifies execution for all skill levels with a clean interface and visual instruction.

Seamless Process Flow

Work instructions, verifications, approvals, and data capture all happen in one place, without switching tools or systems.

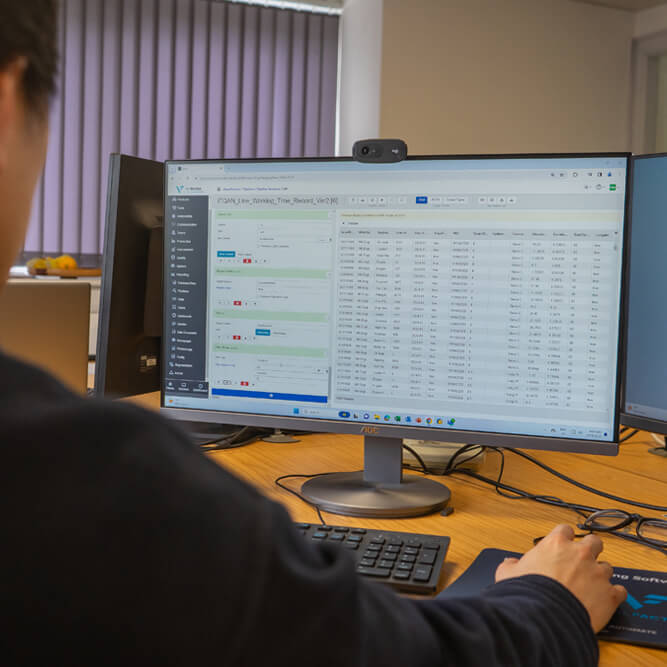

In-Built Compliance & Traceability

Identify who did what, when, and how, with auditable digital records for every part, process, and sign-off.

How Work Order Processing Fits Into Your Workflow

Import Work Order from ERP

Gain orders and configuration data from your ERP system with an automatic sync.

Adapt Steps to Each Build

Create unique work instructions based on order-specific variants and product logic.

Guide Operators Live

Give operators bespoke, step-by-step instructions based on their skillset and real-time process conditions.

Report Execution Data

Record every step, part, and inspection in real time, feeding data back to ERP and dashboards.

Achieve Real Business Impact with Work Order Processing

Increase Build Accuracy

Dynamic instructions and built-in checks decrease errors and ensure every product meets its specifications.

Reduce Operator Onboarding Time

Intelligent instructions guide new hires in performing complex tasks without needing to memorize steps.

Eliminate Manual Admin and Paper

Digitize all assets from work orders to inspections, cutting paperwork, duplication, and delays.

Unlock Lean, Configurable Production

Enable mass customization and complex assemblies without compromising speed or quality.

Partnering with Leaders in

Aerospace & Defense

Ensure compliance with aerospace and defense requirements, like AS9100 and ITAR.

Aerospace & Defence

Automotive & Transport

Enhance automotive and transport delivery performance, with intuitive dashboards that effectively measure OEE.

Automotive & Transport

Consumer Products

Scale confidence and enhance product launches with paperless instructions and integrated quality checks.

Consumer Products

High Tech & Electronics

Improve compliance, scale precision and agility and maintain end‑to‑end traceability for high tech electronics.

High Tech & Electronics

Industrial Products

Transform industrial production with a solution designed for complexity, performance and real time visibility.

Industrial Products

Medical Device Manufacturing

Build safe and compliant products that meet FDA and ISO requirements, with skill validations and audit trails.

Medical Device Manufacturing

Pharmaceutical Manufacturing

Digitize pharmaceutical batch production with a program that supports compliance on the floor.

Pharmaceutical Manufacturing

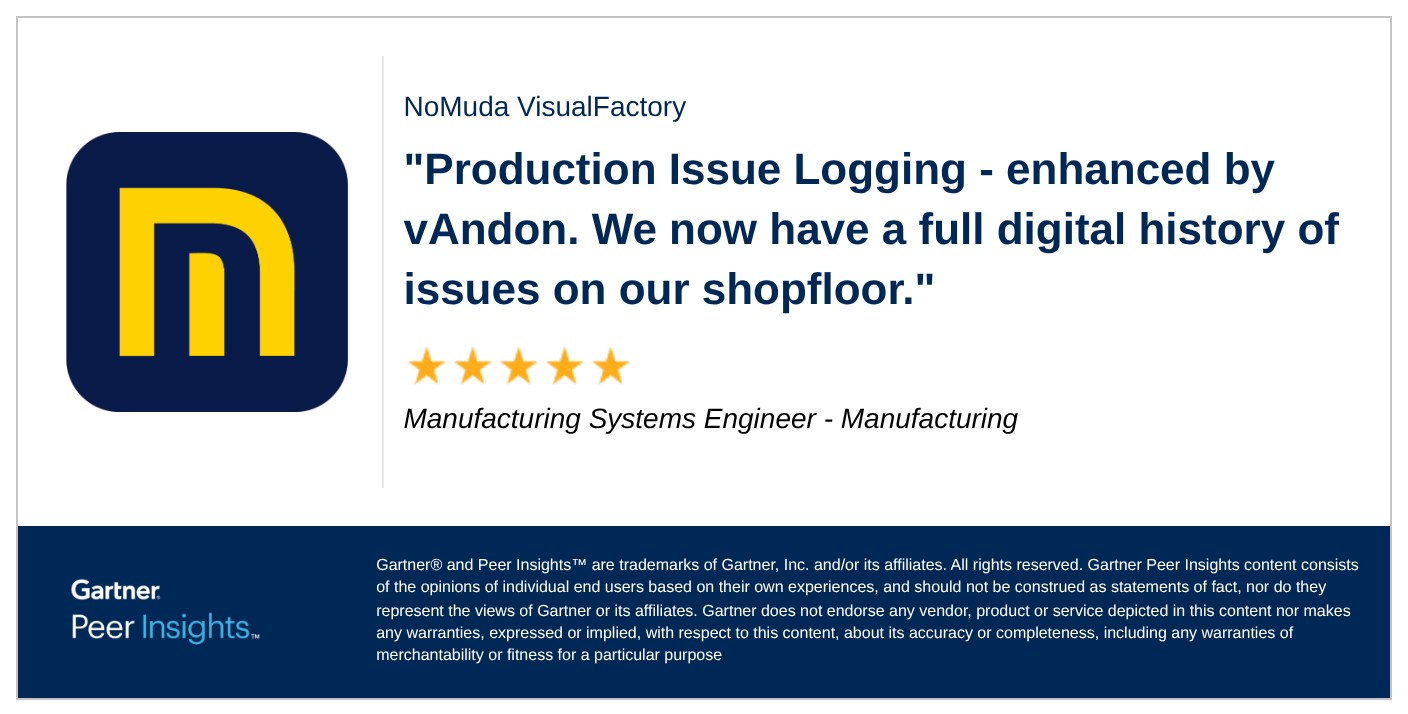

What Clients Say About VisualFactory

Case Studies

Rhopoint Instruments

VisualFactory has provided Rhopoint with a lean manufacturing solution that has transformed their productivity whilst improving first time quality by 35%.

Read more

Volvo

“The possibilities are endless with the constant development of new modules – it is truly a one stop shop for all of your lean manufacturing needs.” – Manufacturing Engineer Garry Moore.

Read more

Saab Seaeye

VisualFactory has reduced Saab Seaeye’s rework costs by more than a quarter of a million dollars by helping them to achieve right-first-time quality.

Read more